1500cc 170Ps How??????

-

Dallarax19

- Beiträge: 10

- Registriert: 13. Nov 2007, 22:26

1500cc 170Ps How??????

This has been discussed but the link went in the direction of piston speed etc. I have 97peak whp (approx 115hp (sae) crank)

Here are the specs:

***I rev this car to 8500-9000rpm nearly every shift*** I wanted to get that off the table

1500cc

10.3/1 cr (domed pistons)

PBS big valve head 41mm intake stock exhaust

40/80 cam with 11.8mm lift

30/45/60 deg valve seat angle

(2) 40 DCOEs (32mm choke) with PBS manifold

Piper adjustable cam gear

4/1 header with 30" to the end of the collector

PBS lightened flywheel 12.4lb (5.6kg)

**Mustang Dyno - conservative numbers***

I have read the Guy Croft pages pretty extensivly , I have the PBS documents, I have the FAZA info, etc and my real qustion is how is everyone getting these high peak numbers? My internals are stock except for my pistons so I have not reduced weight or friction. By extrapolation of the Croft information I would expect my engine to produce 119-127whp (140-150hp crank). That is roughly a 23% increase. Considering the noted differences in G. Crofts info I would expect a 5-10hp difference but not 35 - crank.

Has anyone on this forum made nearly 127whp? If you have please help me understand what you suspect is different in your set up.

Peace,

Brian

Here are the specs:

***I rev this car to 8500-9000rpm nearly every shift*** I wanted to get that off the table

1500cc

10.3/1 cr (domed pistons)

PBS big valve head 41mm intake stock exhaust

40/80 cam with 11.8mm lift

30/45/60 deg valve seat angle

(2) 40 DCOEs (32mm choke) with PBS manifold

Piper adjustable cam gear

4/1 header with 30" to the end of the collector

PBS lightened flywheel 12.4lb (5.6kg)

**Mustang Dyno - conservative numbers***

I have read the Guy Croft pages pretty extensivly , I have the PBS documents, I have the FAZA info, etc and my real qustion is how is everyone getting these high peak numbers? My internals are stock except for my pistons so I have not reduced weight or friction. By extrapolation of the Croft information I would expect my engine to produce 119-127whp (140-150hp crank). That is roughly a 23% increase. Considering the noted differences in G. Crofts info I would expect a 5-10hp difference but not 35 - crank.

Has anyone on this forum made nearly 127whp? If you have please help me understand what you suspect is different in your set up.

Peace,

Brian

- Querlenker

- Moderator

- Beiträge: 4148

- Registriert: 7. Sep 2002, 21:15

- Hat sich bedankt: 13 Mal

- Danksagung erhalten: 9 Mal

Hi Brian,

nobody around here is seeing 170hp from a normally aspirated 1500 in a street car.

There generally aren't many non-turbo engines here in Germany that are very highly developed.

One person here in the forum has a Uno Turbo setup that was taken to 1600cc and runs a larger turbo. It was modified by german Uno Turbo specialist Novitec and has a stated output of 200hp.

Higher numbers such as what you are looking for are usually from race motors with wild cams etc.

Cheers, Ulix

nobody around here is seeing 170hp from a normally aspirated 1500 in a street car.

There generally aren't many non-turbo engines here in Germany that are very highly developed.

One person here in the forum has a Uno Turbo setup that was taken to 1600cc and runs a larger turbo. It was modified by german Uno Turbo specialist Novitec and has a stated output of 200hp.

Higher numbers such as what you are looking for are usually from race motors with wild cams etc.

Cheers, Ulix

Gruß Querlenker

Emerson Fittipaldi - Formula 1 World Champion 1972-1974 :

"...I'm not exaggerating, the X1/9 drives just like a Formula 1. I've not often tested a car with road holding as good and as 'true' as this..."

Emerson Fittipaldi - Formula 1 World Champion 1972-1974 :

"...I'm not exaggerating, the X1/9 drives just like a Formula 1. I've not often tested a car with road holding as good and as 'true' as this..."

-

Dallarax19

- Beiträge: 10

- Registriert: 13. Nov 2007, 22:26

Hello Ulix,

Are you the same Ulix with 95whp on the US web sites? Thanks for the propt reply. We have a holiday today so I am spending time doing research. I agree on your points but spec wise I see the main differeces between my engine and a full race engine is compression, lightening, and friction reduction (see specs). There may be a difference in the cam profile but I believe my profile is a copy of an Alquati cam. Good point though and maybe something to look at again.

I believe the benefit for lightening is really to gain more rpm but peak power for those engines is still in the 7000-8000rpm range and I have dynoed the engine up to 7500 rpm without seeing a peak near 120whp. For friction reduction I would expect a significant improvement in hp and is where I expect to see the greatest difference between my engine and a full race engine. Compression will also have an affect but I don't see that single attribute being the factor for a 20plus% difference. It could be but I don't see it.

I appreciate the commentary. This forum seems to have a good technical base. I inquire now and again on the US forums but I find only 10% of the information correct. Most information is speculative and of opinion. The 10% that is good however is really good. I thought I would give this one a try. Keep the comments coming because I am overlooking something.

Thanks,

Brian

Are you the same Ulix with 95whp on the US web sites? Thanks for the propt reply. We have a holiday today so I am spending time doing research. I agree on your points but spec wise I see the main differeces between my engine and a full race engine is compression, lightening, and friction reduction (see specs). There may be a difference in the cam profile but I believe my profile is a copy of an Alquati cam. Good point though and maybe something to look at again.

I believe the benefit for lightening is really to gain more rpm but peak power for those engines is still in the 7000-8000rpm range and I have dynoed the engine up to 7500 rpm without seeing a peak near 120whp. For friction reduction I would expect a significant improvement in hp and is where I expect to see the greatest difference between my engine and a full race engine. Compression will also have an affect but I don't see that single attribute being the factor for a 20plus% difference. It could be but I don't see it.

I appreciate the commentary. This forum seems to have a good technical base. I inquire now and again on the US forums but I find only 10% of the information correct. Most information is speculative and of opinion. The 10% that is good however is really good. I thought I would give this one a try. Keep the comments coming because I am overlooking something.

Thanks,

Brian

- Querlenker

- Moderator

- Beiträge: 4148

- Registriert: 7. Sep 2002, 21:15

- Hat sich bedankt: 13 Mal

- Danksagung erhalten: 9 Mal

Brian,

yes, same Ulix, except now I just finished a 1600 prepped similar to yours with more CR, but a little less carb and cam with 120 crank hp and a very strong midrange.

I would suggest to look at the overall picture.

We are dealing with a non-crossflow engine of a design that is more than 30 years old (even though it was way ahead at the time). 100hp/L was way hot back then and is still a lot today for that type of motor.

If you want to exceed that and go to say 170hp from a 1500 (with carbs and w/o forced induction), you are not talking about a street motor anymore.

You are talking 2000 rpm idle and undriveable in traffic.

Yes, you may be taking your engine to the same rpm where a race motor is making its power, but with only a 40/80 cam, you are far from making the same power.

The way I look at this, I would be happy with the good power you are getting and work on driveability and a wide powerband instead of peak hp.

yes, same Ulix, except now I just finished a 1600 prepped similar to yours with more CR, but a little less carb and cam with 120 crank hp and a very strong midrange.

I would suggest to look at the overall picture.

We are dealing with a non-crossflow engine of a design that is more than 30 years old (even though it was way ahead at the time). 100hp/L was way hot back then and is still a lot today for that type of motor.

If you want to exceed that and go to say 170hp from a 1500 (with carbs and w/o forced induction), you are not talking about a street motor anymore.

You are talking 2000 rpm idle and undriveable in traffic.

Yes, you may be taking your engine to the same rpm where a race motor is making its power, but with only a 40/80 cam, you are far from making the same power.

The way I look at this, I would be happy with the good power you are getting and work on driveability and a wide powerband instead of peak hp.

Gruß Querlenker

Emerson Fittipaldi - Formula 1 World Champion 1972-1974 :

"...I'm not exaggerating, the X1/9 drives just like a Formula 1. I've not often tested a car with road holding as good and as 'true' as this..."

Emerson Fittipaldi - Formula 1 World Champion 1972-1974 :

"...I'm not exaggerating, the X1/9 drives just like a Formula 1. I've not often tested a car with road holding as good and as 'true' as this..."

hmm

What head prep did you do?

Pictures? Something done on the valves? Bigger? Other angles? Extra cuts?

How much lift in TDC has the camshaft?

Ignitionsystem?

Fuel?

Plugs?

Exhaust manifold is maybe not very good, but at which rev do you have your maximum output?

Pictures? Something done on the valves? Bigger? Other angles? Extra cuts?

How much lift in TDC has the camshaft?

Ignitionsystem?

Fuel?

Plugs?

Exhaust manifold is maybe not very good, but at which rev do you have your maximum output?

-

Dallarax19

- Beiträge: 10

- Registriert: 13. Nov 2007, 22:26

Here is information that may answer your question

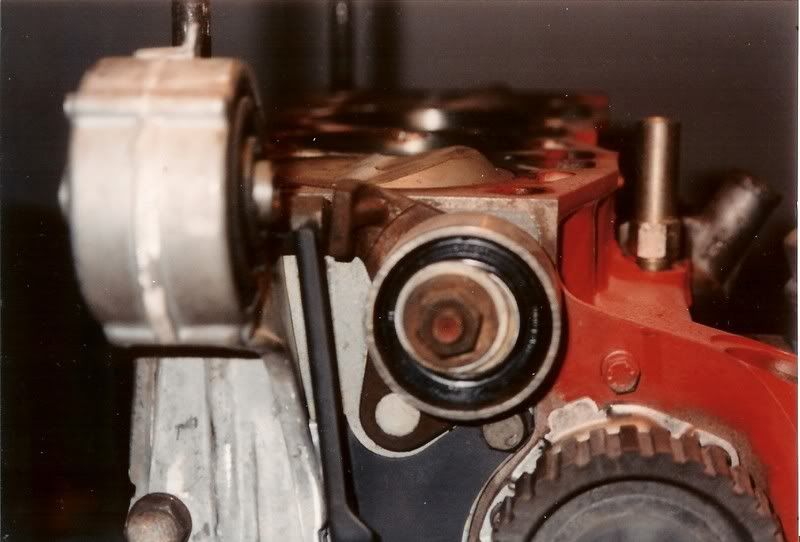

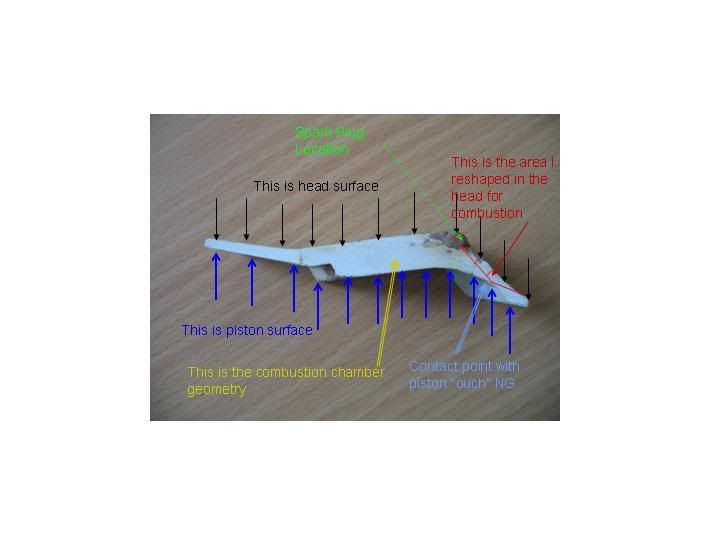

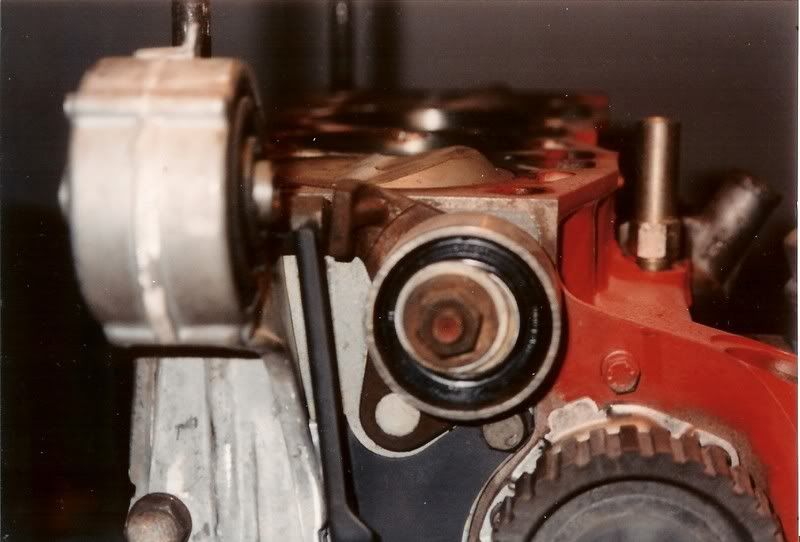

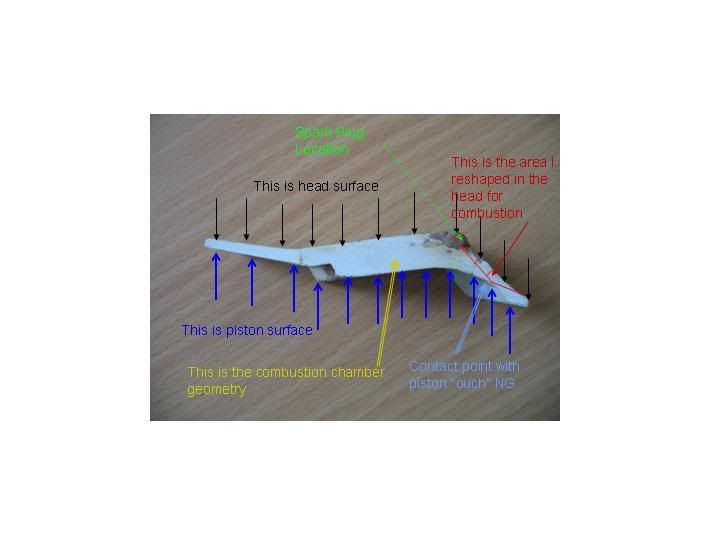

The pictures really tell the story on the head:

Intake valve is 41mm and the exhaust is 33mm (stock)

Lift at TDC = I will need to calculate

Ignition system is Fiat electronic coupled with a MSD 6A

Fuel is 92 Oct

Plugs = RN9Y Campion

Peak Power is 96.6whp@7002rpm

So with all this what are your thoughts? What are you looking for/at?

Thanks,

Brian

The pictures really tell the story on the head:

Intake valve is 41mm and the exhaust is 33mm (stock)

Lift at TDC = I will need to calculate

Ignition system is Fiat electronic coupled with a MSD 6A

Fuel is 92 Oct

Plugs = RN9Y Campion

Peak Power is 96.6whp@7002rpm

So with all this what are your thoughts? What are you looking for/at?

Thanks,

Brian

-

Dallarax19

- Beiträge: 10

- Registriert: 13. Nov 2007, 22:26

Interesting comment on the head. What are your basing your comments on? Actually it is not my first but the head is primarily PBS machined so I am interested on your response. I have to ask too, what is your current hp rating and are you running a 1.5ltr? I only look at data so please let me know what you are basing your comments on.

Yes it is a low octane engine. I use it on the street as well as the track. That is the limiting factor for the compression ratio. The compression ratio was determined by casting the combustion chamber and measuring the amount of water displaced when the cast was submerged. I belive the ratio is correct.

I will dig through my archives for picture of the piston. They are Kolben Schmidt 13/1 pistons so if you are familiar with those you will know the shape. Again I appreciate the comments but please show data.

Brian

Yes it is a low octane engine. I use it on the street as well as the track. That is the limiting factor for the compression ratio. The compression ratio was determined by casting the combustion chamber and measuring the amount of water displaced when the cast was submerged. I belive the ratio is correct.

I will dig through my archives for picture of the piston. They are Kolben Schmidt 13/1 pistons so if you are familiar with those you will know the shape. Again I appreciate the comments but please show data.

Brian

Saubere Arbeit

endlich jemand, der die Kerzenwand bearbeitet.

sehe da ein gut gemachten Brennraum

sehe da ein gut gemachten Brennraum

fehlende Leistung wird durch Wahnsinn ersetzt

Peter an der Halbkugelform finde ich nichts besonderes. Finde die eher kontraproduktiv bei unseren Köpfen.

Quetschkanten und die sind dort komplett weg.

Übergänge von Quetschkanten möglichst Scharfkantig.

Gegenüber der Zündkerze breche ich die Kante auch. Hab ich beim Turbo schon gute Erfahrungen gemacht.

Dort ist mir gedoch aufgefallen das es eine Überfettung im Bereich der Auslassventile gibt (dort ist der Kopf und der Kolben schwarz, sonst nicht?!).

Diese Einbohrung im Brennraum damit die Kerze richtig reinragt, die habe ich auch etwas vergrößert bei meinem Bruder.

That's why I'm asking about the head prep:

It's cool that you have 100hp with 92octan.

You drive very hot spark plugs. It's like a Bosch 7 plug.

Ok with your ignition system you will not have problems because of the plugs.

I think you should try a aftermarket ignition system (Jaycar should run fine).

Quetschkanten und die sind dort komplett weg.

Übergänge von Quetschkanten möglichst Scharfkantig.

Gegenüber der Zündkerze breche ich die Kante auch. Hab ich beim Turbo schon gute Erfahrungen gemacht.

Dort ist mir gedoch aufgefallen das es eine Überfettung im Bereich der Auslassventile gibt (dort ist der Kopf und der Kolben schwarz, sonst nicht?!).

Diese Einbohrung im Brennraum damit die Kerze richtig reinragt, die habe ich auch etwas vergrößert bei meinem Bruder.

That's why I'm asking about the head prep:

It's cool that you have 100hp with 92octan.

You drive very hot spark plugs. It's like a Bosch 7 plug.

Ok with your ignition system you will not have problems because of the plugs.

I think you should try a aftermarket ignition system (Jaycar should run fine).

-

Dallarax19

- Beiträge: 10

- Registriert: 13. Nov 2007, 22:26

Acki

Here is the picture of the piston I said I would post. It is only good one I could find.

I modified the combustion chamber to work with the high compression pistons. The shroud around the valves was releived as well as the pinch point below the spark plug. Without doing that the burn front would be stopped before it reached that pinched off area. I spent quite a bit of time getting this right.

I can't translate all of your comments but it appears you may be missing some fundamentals, maybe it is my translator, I don't know. I will respond to your comments as I understand them.

1) RN9Y Spark plugs are stock Fiat spec for US cars. They are not what I would call hot they are pretty much mid pack. http://sparkplugs.com/sparkplug411.asp? ... %29&mfid=0

2) MSD is an aftermarket ignition system, I believe you are not familiar with it so here is the link

http://www.msdignition.com/ignition_4_6200.htm

I think you may have an issue with the port. The photo is pretty poor but I don't have another that close. The jury is out on that one. Guy Croft is adamant the port shoud be straight however the last CFD my friend and I ran it appeared a slight curve is best. My port has a slight curve. I am looking to bench flow the head as soon as I can.

So with that said what technical solutions do you have to offer. I may not understand your post clearly but it appears you are offering subjective opinions. As you know it takes quite a bit of time to respond the these forums and I don't want to spend my time unwisely. If you have data please provide it, i.e. the port photo, what exactly don't you like about it and why? Mark it up like the example above and post it. Pictures speak a 1000 words and there won't be and language interpretation.

Thanks,

Brian

Here is the picture of the piston I said I would post. It is only good one I could find.

I modified the combustion chamber to work with the high compression pistons. The shroud around the valves was releived as well as the pinch point below the spark plug. Without doing that the burn front would be stopped before it reached that pinched off area. I spent quite a bit of time getting this right.

I can't translate all of your comments but it appears you may be missing some fundamentals, maybe it is my translator, I don't know. I will respond to your comments as I understand them.

1) RN9Y Spark plugs are stock Fiat spec for US cars. They are not what I would call hot they are pretty much mid pack. http://sparkplugs.com/sparkplug411.asp? ... %29&mfid=0

2) MSD is an aftermarket ignition system, I believe you are not familiar with it so here is the link

http://www.msdignition.com/ignition_4_6200.htm

I think you may have an issue with the port. The photo is pretty poor but I don't have another that close. The jury is out on that one. Guy Croft is adamant the port shoud be straight however the last CFD my friend and I ran it appeared a slight curve is best. My port has a slight curve. I am looking to bench flow the head as soon as I can.

So with that said what technical solutions do you have to offer. I may not understand your post clearly but it appears you are offering subjective opinions. As you know it takes quite a bit of time to respond the these forums and I don't want to spend my time unwisely. If you have data please provide it, i.e. the port photo, what exactly don't you like about it and why? Mark it up like the example above and post it. Pictures speak a 1000 words and there won't be and language interpretation.

Thanks,

Brian

Ahh ok. I have read it to fast. I thought you written MED - Mikroplex or something like this.

Standard plugs are to hot for tuning. On my turbo my standard plugs burned down

Most guys I know drive Bosch 5 platin plugs.

Now I understand your picture. Nice idea

Nice idea

Can't you bring the CR a little bit higher and try high octan fuel? To drive more ignition?

That's the head of my brothers engine:

1602cc CR also ~10:1 but we don't have dome pistons

CR also ~10:1 but we don't have dome pistons  This shall be the next step with this engine but first we will try if the engine works good. Camsaft is 316° with 4mm lift in TDC.

This shall be the next step with this engine but first we will try if the engine works good. Camsaft is 316° with 4mm lift in TDC.

I think you have removed to much the squish zones. On a 4 valves head it can be better when you remove them but then you have a squish because the chamber is smaller then the bore and you have a squish with the piston. But both we don't have.

Ok GC says squishzones are only for slow running engines. On race engines with a power band from 5000rpm+ you can ignor this but I don't know...

I see it on the pistons of 1602 turbo's which are cutted down for lower CR and on the stock pistons of the 1301cc turbo's..

The cutted pistons are complete black - too rich mixtures maybe and the 1301cc turbo pistons are not complete black, they are yellow around the inlet valves and only black around the exhaust valve. I think you could squish the mixture in this area a little bit more to bet also a yellow color. On a turbo engine I would favorite a wave or curve in the pistons dish from exhaust (high) to inlet (lower).

But maybe I think too much about those things.

With a CFD software I could simulate it. Maybe I find some days time to make it.

Standard plugs are to hot for tuning. On my turbo my standard plugs burned down

Most guys I know drive Bosch 5 platin plugs.

Now I understand your picture.

Can't you bring the CR a little bit higher and try high octan fuel? To drive more ignition?

That's the head of my brothers engine:

1602cc

I think you have removed to much the squish zones. On a 4 valves head it can be better when you remove them but then you have a squish because the chamber is smaller then the bore and you have a squish with the piston. But both we don't have.

Ok GC says squishzones are only for slow running engines. On race engines with a power band from 5000rpm+ you can ignor this but I don't know...

I see it on the pistons of 1602 turbo's which are cutted down for lower CR and on the stock pistons of the 1301cc turbo's..

The cutted pistons are complete black - too rich mixtures maybe and the 1301cc turbo pistons are not complete black, they are yellow around the inlet valves and only black around the exhaust valve. I think you could squish the mixture in this area a little bit more to bet also a yellow color. On a turbo engine I would favorite a wave or curve in the pistons dish from exhaust (high) to inlet (lower).

But maybe I think too much about those things.

With a CFD software I could simulate it. Maybe I find some days time to make it.

-

Dallarax19

- Beiträge: 10

- Registriert: 13. Nov 2007, 22:26

Update if info

This was recorded yesterday. Some balancing needed but better than expected. Working on a CAE solution for ultimate power. I will post my progress in the future.

Brian

Brian

- Holgi

- Site Admin

- Beiträge: 5577

- Registriert: 6. Sep 2002, 19:24

- Hat sich bedankt: 35 Mal

- Danksagung erhalten: 20 Mal

Brian, seems to be reasonable work you are doing!

Just a quick question on the CFD calculations:

How have you transfered the original port shape into the digital world?

Have you included the valves in the simulation and tried unsteady flow simulation

(including piston movement) to come up with trapped mass?

Do you have an explanation for the variations in the flow rates of cyl. 1-4?

What is the "generic mod bench" curve? Could you explain?

Just a quick question on the CFD calculations:

How have you transfered the original port shape into the digital world?

Have you included the valves in the simulation and tried unsteady flow simulation

(including piston movement) to come up with trapped mass?

Do you have an explanation for the variations in the flow rates of cyl. 1-4?

What is the "generic mod bench" curve? Could you explain?

Bertone X1/9

-

Dallarax19

- Beiträge: 10

- Registriert: 13. Nov 2007, 22:26

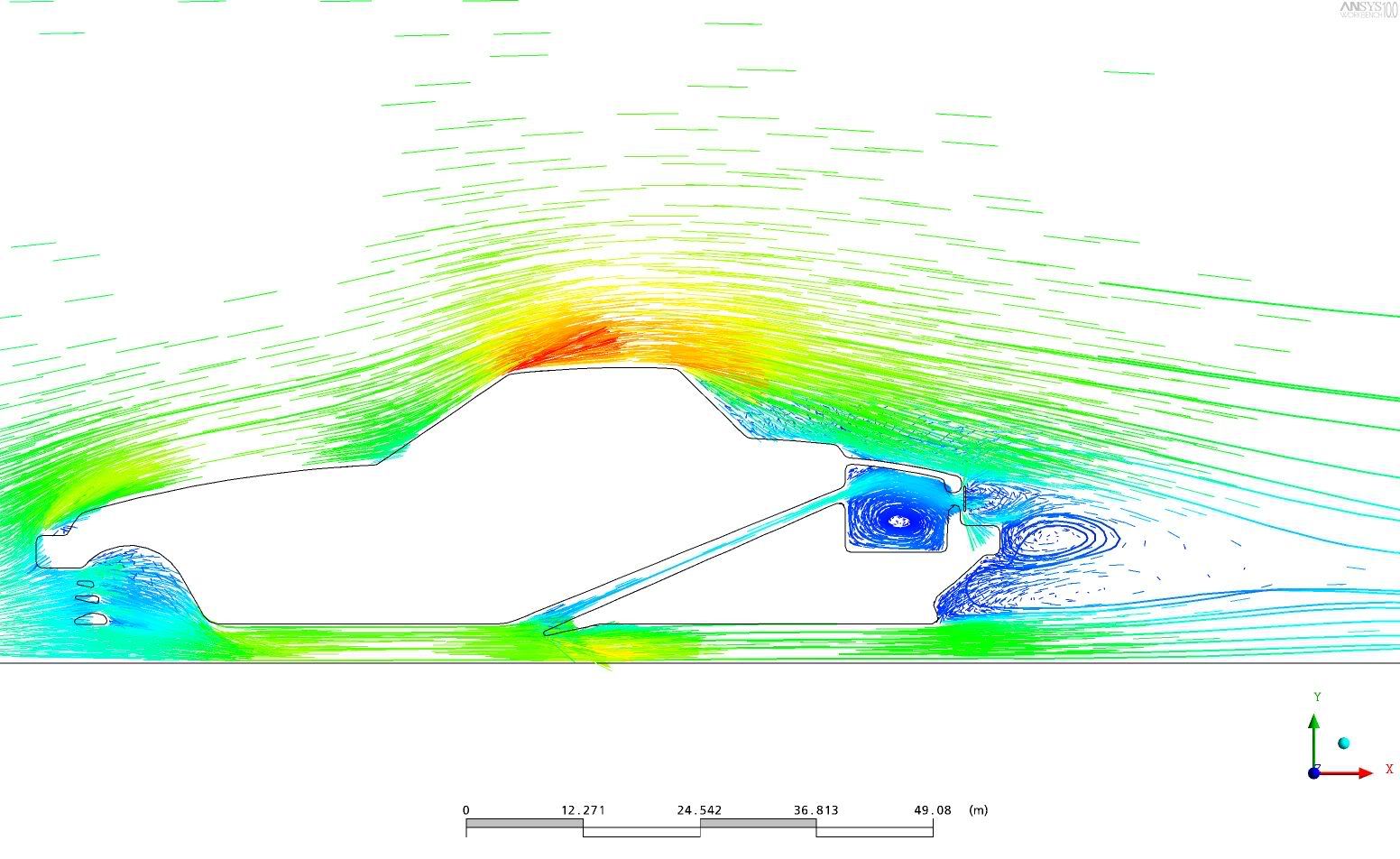

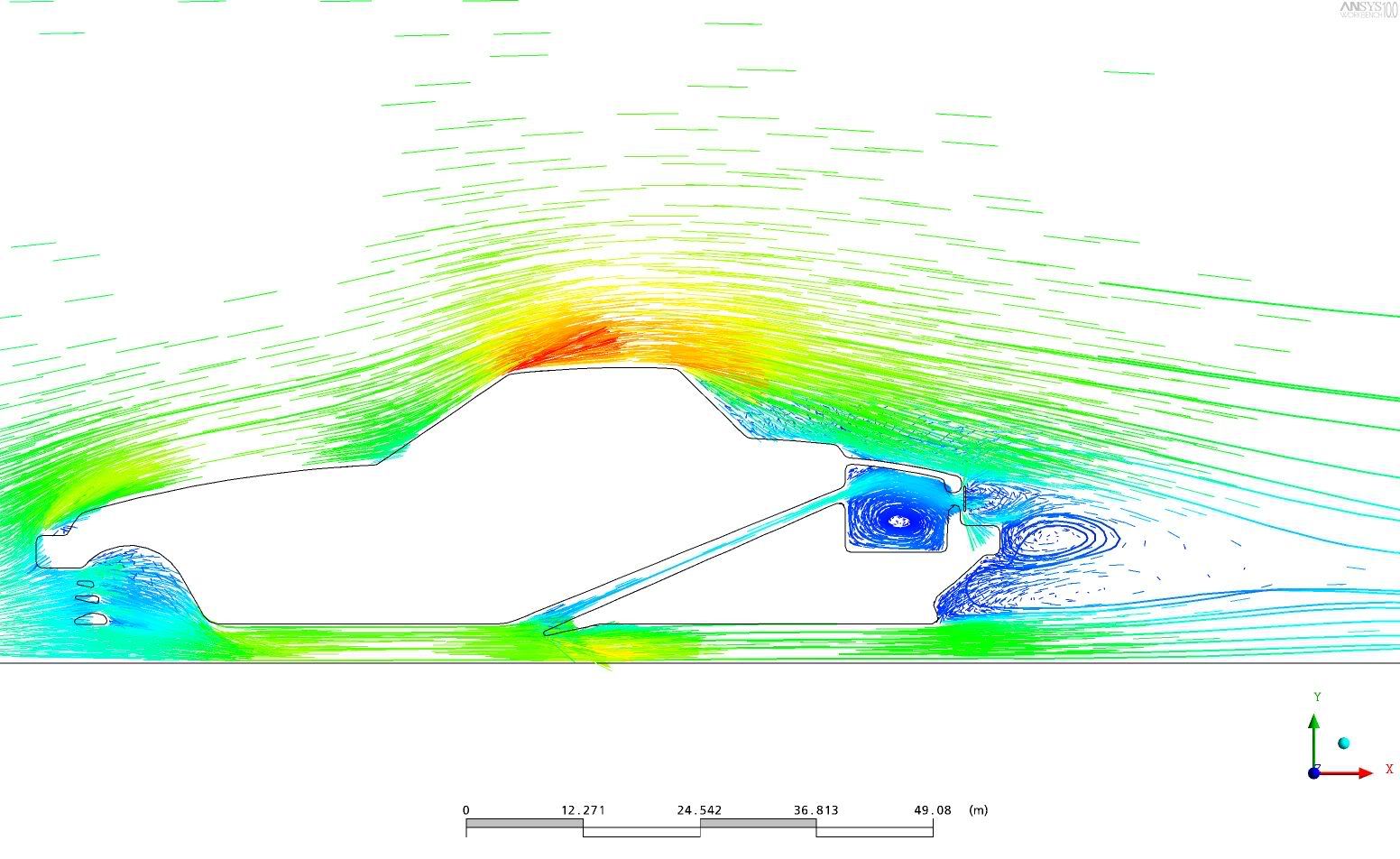

Acki, I could not translate your comment so I don't have a response. Pauer, yes I have the port CFD. Actually my friend Brad Garska did the analysis and I think it was in ANSYS. No transient analysis with dynamic movement, nothing that involved. It is all at steady state and simple. I am traveling so I don't have the port jpg to send but here is a quick study he did for an oil cooler in his trunk:

I ported a cylinder head 17years ago and cut into the water jacket, 2mm shorter and I would have been safe, I could not weld it up so I sectioned it for reference. Between my sectioned head and the multiple cross sections in the Fiat and FAZA manuals we modeled it.

The valve was not added in the analysis it was just an open port simulation. With that said the engine is simulated with a "canned" program that Brad has. I apologize but I can't remember which one. I works off of input effiency coefficients and empirical curves. Surprising enough it is very comprehensive. We have worked together and Brad has a very good dyno curve that matches pretty closely to my empirical data. As I get real data he adds it to his model and we work together to look at various alternatives that would improve the Hp.

I believe the differences in the flow are due to minor differences in the port and large differences in the combustion chamber. They are just not balanced out. I need to match ports/chamber 1,3,4 to cyl #2 . I expect the differences will be very subtle so I will have to be very careful. For the ports I will probably start with silicone casts and for the chambers I will probably make plaster casts. I no longer have a contact to digitize the surface and frankly I would have a rough time of surfacing the data - it has been quite some time since the last time I surfaced anything.

The "generic mod bench" means the generic modified head benchmark. In my collection of reference data I have a page from a head tuning book that happens to have a Fiat SOHC head as an example. It has a standard head and a "modified head" bench flow curve.

Pretty much my next steps are derived from a collection of simple CAE work, analysis of my empirical data (calcs etc), and cross referencing existing documentation. Hopefully I have answered your questions.

I will post data as I get it.

Brian

I ported a cylinder head 17years ago and cut into the water jacket, 2mm shorter and I would have been safe, I could not weld it up so I sectioned it for reference. Between my sectioned head and the multiple cross sections in the Fiat and FAZA manuals we modeled it.

The valve was not added in the analysis it was just an open port simulation. With that said the engine is simulated with a "canned" program that Brad has. I apologize but I can't remember which one. I works off of input effiency coefficients and empirical curves. Surprising enough it is very comprehensive. We have worked together and Brad has a very good dyno curve that matches pretty closely to my empirical data. As I get real data he adds it to his model and we work together to look at various alternatives that would improve the Hp.

I believe the differences in the flow are due to minor differences in the port and large differences in the combustion chamber. They are just not balanced out. I need to match ports/chamber 1,3,4 to cyl #2 . I expect the differences will be very subtle so I will have to be very careful. For the ports I will probably start with silicone casts and for the chambers I will probably make plaster casts. I no longer have a contact to digitize the surface and frankly I would have a rough time of surfacing the data - it has been quite some time since the last time I surfaced anything.

The "generic mod bench" means the generic modified head benchmark. In my collection of reference data I have a page from a head tuning book that happens to have a Fiat SOHC head as an example. It has a standard head and a "modified head" bench flow curve.

Pretty much my next steps are derived from a collection of simple CAE work, analysis of my empirical data (calcs etc), and cross referencing existing documentation. Hopefully I have answered your questions.

I will post data as I get it.

Brian